Hydrocarbon Pipeline Materials

The selection of material for oil pipelines is a critical decision that affects the pipeline's strength, durability, corrosion resistance, and cost. Here are five materials that are commonly used in oil pipeline construction:

Carbon Steel

This is the most commonly used material for oil pipelines. It offers a good balance of strength, durability, and cost-effectiveness. The grade of carbon steel chosen often depends on the conditions expected on the route, such as soil type and temperature

Low-Alloy Steel

These are used for pipelines that need higher strength and toughness than carbon steel can provide, such as in very cold or very hot environments, or when the oil is particularly corrosive.

Corrosion-Resistant Alloys (CRAs)

These alloys, including stainless steel and nickel alloys, are used for pipelines that transport highly corrosive oil, such as oil with a high sulfur content. CRAs are more expensive than carbon steel but offer superior corrosion resistance.

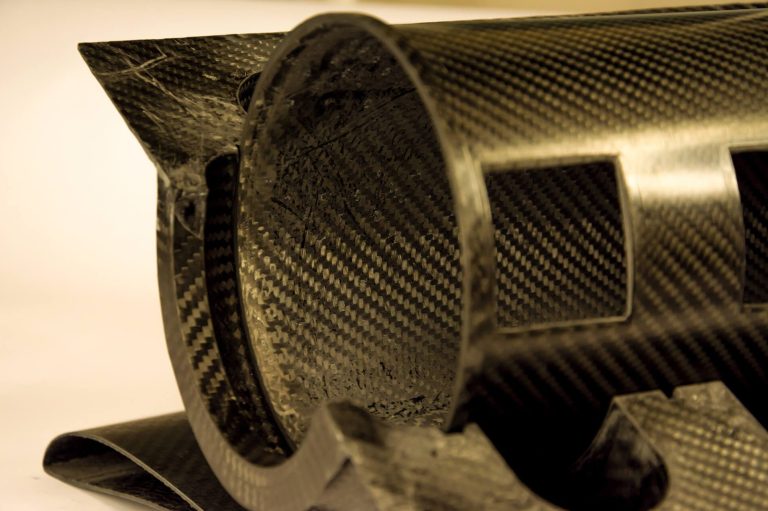

Composite Materials

Composite materials, such as fiberglass reinforced plastic (FRP), can be used in certain situations. They are resistant to corrosion and have a high strength-to-weight ratio, but they are more expensive and less proven in large-scale oil pipelines than steel.

Duplex Stainless Steel

This material has higher strength and better corrosion resistance than standard stainless steel. It is often used in offshore pipelines or other harsh environments, although it is more expensive than carbon steel.

Contact Us...

We have many more solutions available for more complex projects so feel free to contact us for further information and tailored suggestions to suit your needs

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.